PLC Based Steam Kettle

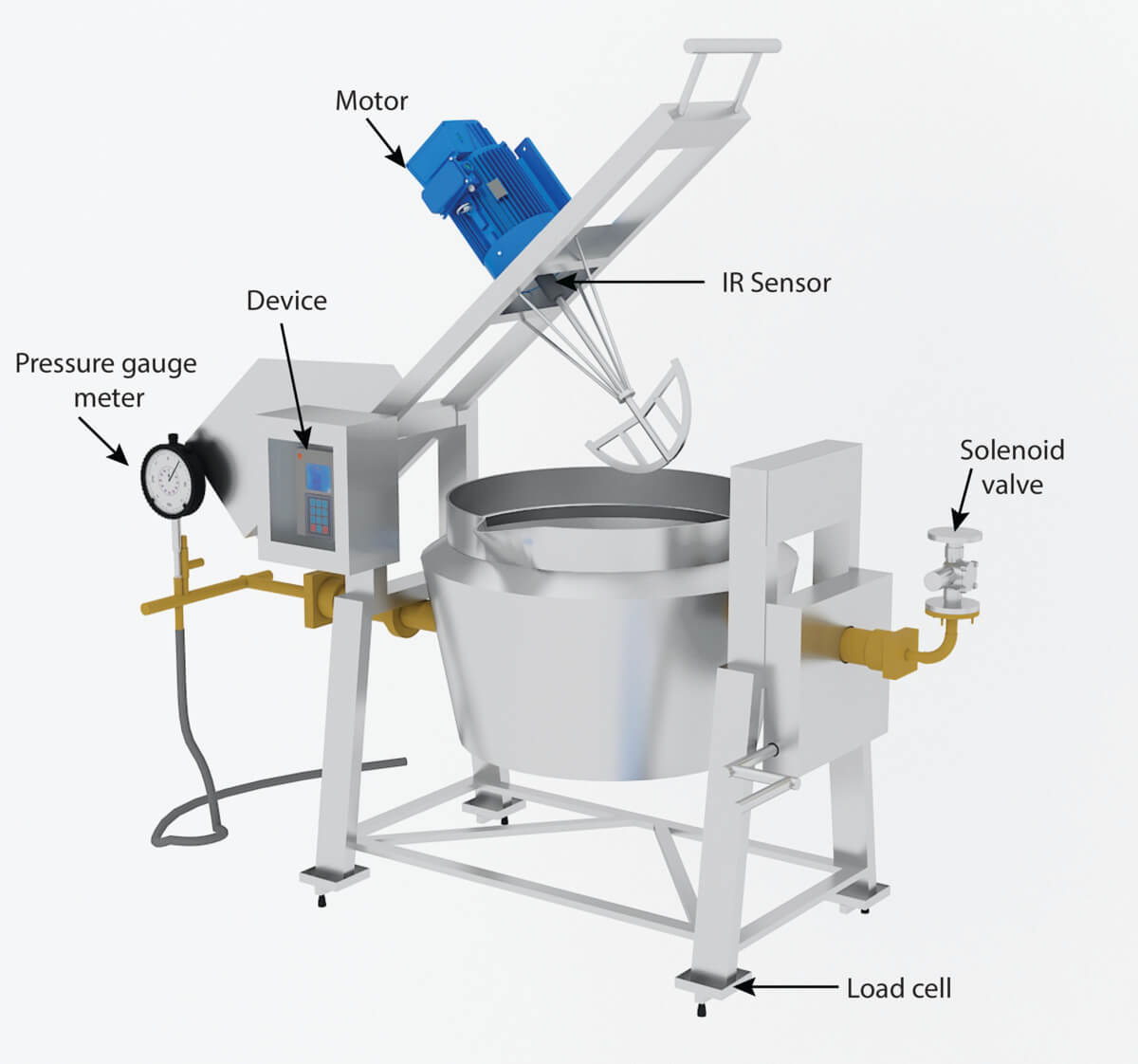

About Device

Monitoring and controlling various parameters such as raw material weight, cooking temperature, cooking time, and accommodating multiple recipes pose challenges in traditional steam kettle operations.

To monitor and control

- Weight of the raw material

- Cooking temperature

- Cooking time

- Multiple Recipes as required

How PLC based steam kattle operates?

- PLC is connected to WEIGHT SENSORS to monitor the weight of the raw materail. If raw materail weight is less than or more than the programed value the kettle will stop and indicate by an alarm / buzzer.

- PLC is connected to an IR SENSOR and SOLENOID VALVE through which we can control the Temperature.

- PLC has an INTERNAL TIMER, when the process is complete the machine automatically stops working and indicates by alarm/ buzzer.

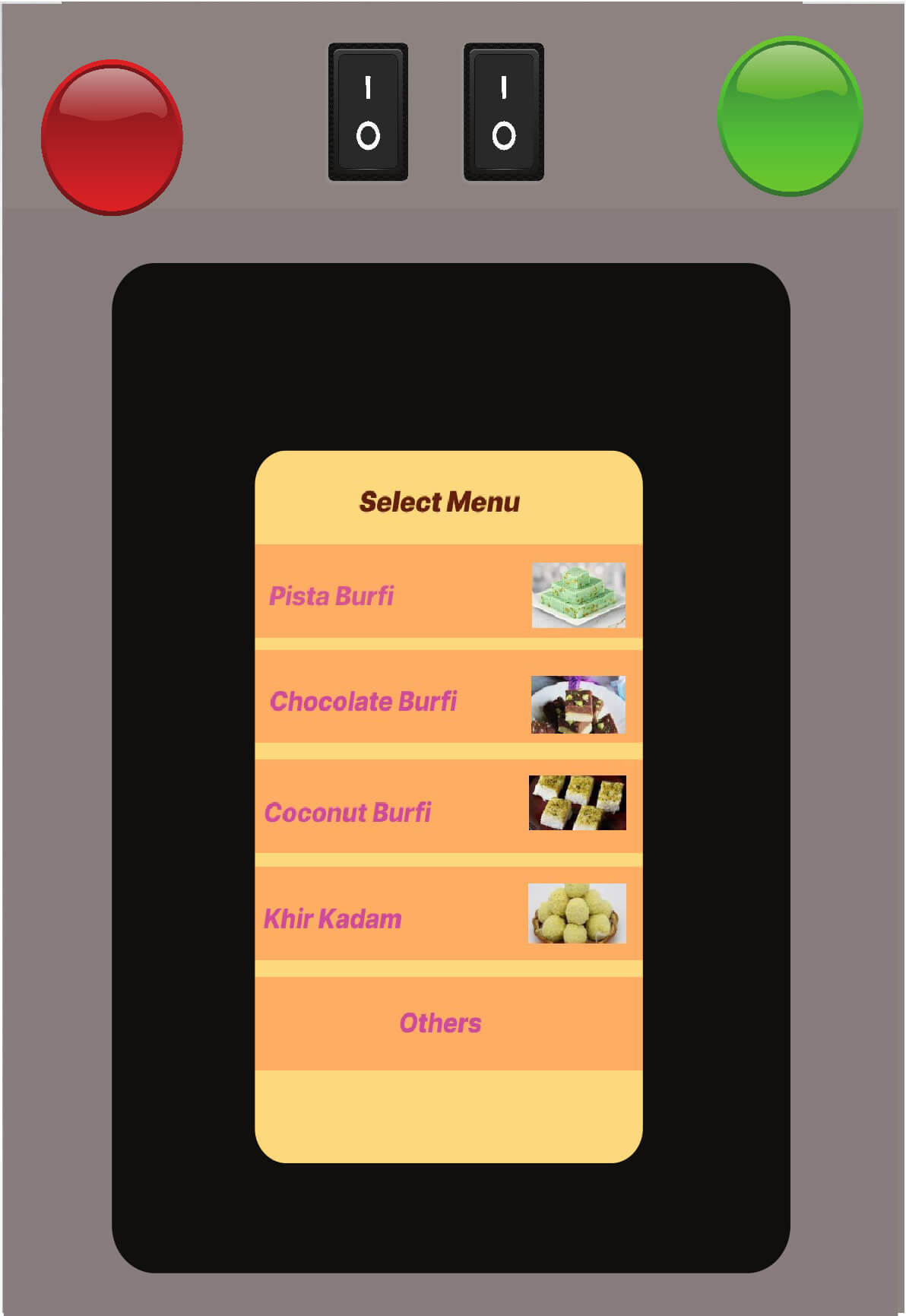

- PLC has multiple recipes which can be selected by the operator.

Features

- Equipped with a 32-bit microcontroller and a 9-inch touch screen TFT

- Monitors raw material weight using connected weight sensors, halting operation and signaling with an alarm if the weight deviates from programmed values.

- Controls temperature via an IR sensor and pilot operated piston type solenoid valve

- Incorporates an internal timer to automatically stop operation upon completion of the cooking process, signaling with an alarm

- Offers multiple recipes for operator selection